Mesh CBN

Mesh cubic boron nitride (cBN) is a superabrasive material with a crystal structure similar to synthetic diamond, providing superior wear and oxidation resistance to ferrous materials. It is used in grinding and finishing applications of ferrous materials where high precision and fine surface finishes are required, especially for hard materials such as hardened steels, superalloys, and ceramics.

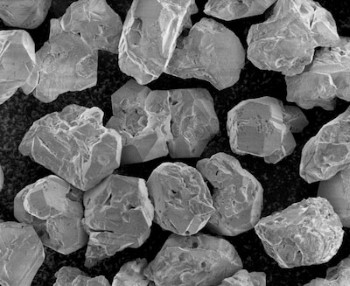

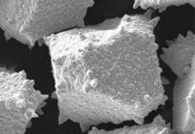

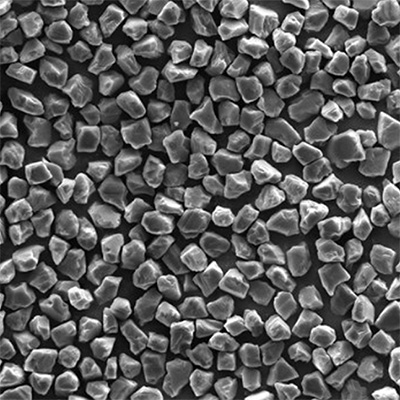

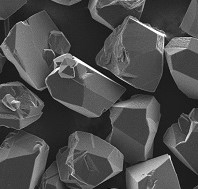

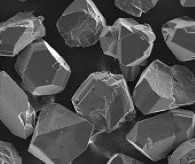

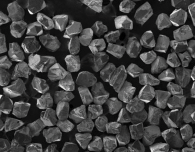

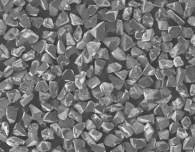

The morphology and shape of cBN particles play a critical role in the free cutting ability and life of the tool. Our range of cBN products incorporates a variety of shapes each tailored to suit a particular application and bond system.

Our mesh cBN products are available in ANSI particle (grit) sizes from 20/30 to 325/400.

Products

Borazon™ CBN Electroplated / Single Layer

Hyperion Code: Borazon 700/300/500/570

Grading: Mesh/FEPA

Description: CBN crystals tailored for electroplating and other single layer systems.

Borazon™ CBN Metal Bond Systems

Hyperion Code: Borazon 550(Ti)/510

Grading: Mesh/FEPA

Description: CBN crystals tailored for metal bond systems. Both uncoated and coated crystals are available.

Borazon™ CBN Resin Bond Systems

Hyperion Code: Borazon 560/520/420/415/1200/Type II & III/SP2S

Grading: Mesh/FEPA

Description: CBN crystals tailored for resin bond systems. All crystals in this category are coated to achive high performance and stable attrition.

Borazon™ CBN Vitrified Bond Systems

Hyperion Code: Borazon VBR/400/1000/Type I/SPS1

Grading: Mesh/FEPA

Description: CBN crystals tailored for vitrified bond systems. Both uncoated and coated crystals are available.

cBNMesh Electroplated Bond Systems

Hyperion code: cBN G3/GPR7

Grading: Mesh/FEPA

Description: CBN crystals combined with electroplated bonds maintain high cutting and grinding manufacturing performance with excellent accuracy and efficiency. Therefore, it is often used for grinding wheels and on tools of ferrous materials.

cBNMesh Metal Bond Systems

Hyperion code: cBN M6

Grading: Mesh/FEPA

Description: CBN crystals combined with metal bonds maintain a long useful tool life with a reduction in the frequency of dressing. It is often used for grinding wheels and on tools of ferrous materials, carbide, ceramics, and quartz.

cBNMesh Resin Bond Systems

Hyperion code: cBN R2/R82/G3/K8

Grading: Mesh/FEPA

Description: CBN crystals combined with resin bonds enhance the tool’s performance on the material. It is often used for grinding wheels and on tools of ferrous materials, carbide, ceramics, and quartz.

cBNMesh Vitrified Bond Systems

Hyperion code: cBN K8/M6

Grading: Mesh/FEPA

Description: CBN crystals combined with vitrified bonds to create a glassy or “glass bond” material best suited for rough grinding, semi-finish grinding, finish grinding, polishing, molding, and edge preparation.

Mesh cBN Applications

With its ability to not chemically wear in the presence of graphite or carbide during the abrasive process, mesh cBN is explicitly designed for applications involving ferrous materials. Mesh cBN is mainly used in grinding ferrous materials like cast iron, wrought iron, steel, nickel alloys, and stainless steel.

Mesh cBN is often used in the production of cutting tools, dies, knives, saw blades, bearing rings, compressor parts, engine components, turbine parts, gears, and various other metal tools.

Mesh cBN Products

Borazon™ CBN Family

Our Borazon™ CBN products provide exceptional thermal conductivity and improved surface integrity in the grinding of a hardened tool, die, and alloy steels, as well as nickel- and cobalt-based superalloys. We offer a complete range of Borazon CBN products created specifically for differing bond systems: electroplated, metal, resin, and vitrified. From blocky to angular shapes and friable to tough crystal strengths, we have the product to optimize your tool performance.

CBNMesh Product Family

Available in a wide variety of sizes, we offer a wide range of CBNMesh products such as CBNMesh Electroplated, CBNMesh Metal, CBNMesh Resin, and CBNMesh Vitrified bond systems that are best used in grinding wheels for a myriad of applications: high stock removal, surface grinding, profile grinding, surface finishing, and sharpening steel cutters.

At Hyperion Materials & Technologies, we offer numerous crystal coatings and surface treatments to impart different performance characteristics. The coatings improve performance through greater crystal retention, heat transfer, and lubricating qualities. Coatings include nickel, titanium, and copper in differing weight percentages.

Hyperion also manufactures a range of micron cBN powders and micron diamond powders as well as high quality mesh diamonds.

Frequently Asked Questions about Micron Diamond Powders

Micron diamond powder is an ultra-fine diamond particle manufactured through a controlled process and available in various particle sizes to produce grinding, lapping, and polishing of hard and abrasive materials.

Mesh cBN is different from industrial diamonds because it is made of boron and nitrogen and is synthesized to be tailored to provide the required characteristics to grind and finish ferrous tools. Industrial diamonds are superabrasives made of pure carbon and are used to grind and finish nonferrous tools. Mesh cBN also has a thermal stability higher than that of industrial diamond, which means it can withstand higher temperatures without breaking down or losing its cutting ability.

The color of cBN is different from that of industrial diamonds because of its chemical composition. CBN contains boron and nitrogen, which give it a distinct light brown or amber color. Variances in cBN color manifests itself in performance depending on the tool type and application. For example, a boron-rich material is often considered more challenging to see in electroplated tools since it can lead to over-plating.

CBN is sometimes coated with a thin layer of material, such as titanium, nickel, or copper, to improve its performance in certain industrial applications. Crystal coatings and surface treatments of cBN enhance crystal retention, improve bonding, increase durability, reduce friction, and in some cases provides lubrication characteristics.

CBN is used for tools designed to work on ferrous workpiece materials such as hardened steel, bearing steel, nickel-based alloys, and superalloys.

CBN can be used in grinding wheel bond systems using vitrified bonds for machine shops to produce engine components such as cam and crankshafts for the automotive industry.

Specially cleaned and shaped cBN grades are used to produce grinding wheel bond systems of single layers (electroplated) for precision grinding turbine components, such as vanes, blades, and nozzles, and for seals for the aerospace industry.

Titanium-coated cBN is used in metal and hybrid bond systems to produce tools for profile grinding. Nickel-coated cBN is used in resin bond systems to produce precision components in machine tools and die and mold industries.